LCEsmartr has been updated. If you haven’t logged in since June 30, 2025, you’ll need to reset your password.

The LCEsmartr playbook is an asset management and reliability accelerator—a toolkit and coach complete with:

Implementation Guide

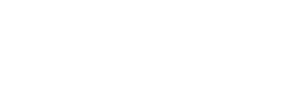

The implementation guide is organized into five phases involved in a reliability and asset management transformation. Each phase contains detailed guidance and tools you’ll need to be successful, from partnership agreements to business case presentations and more.

The Five Stages of a Transformation

Table of Contents

Phase 1: Visualize

Phase 2: Prepare

Phase 3: Design

Phase 4: Deploy

Phase 5: Sustain

Assessments

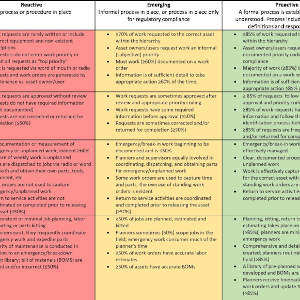

Assessments in the smartrPlaybook examine current reliability processes and practices as compared to industry accepted best practices.

Work Stream Assessments

Reliability Engineering

Work Management

Materials Management

Capital Delivery

Design for Reliability

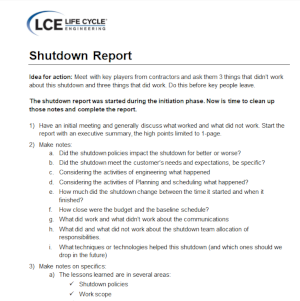

Shutdowns, Turnarounds, and Outages

Work Streams

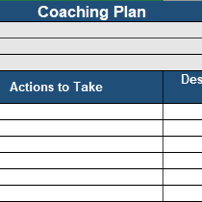

A core section of the Playbook that includes fully developed business process models that are standardized across industries. Each work stream includes work process flow charts, process step definitions, responsibility matrixes, and coaching cards for sustainability.

Work Streams

Reliability Engineering

Work Management

Materials Management

Capital Delivery

Design for Reliability

Shutdowns, Turnarounds, and Outages

Tools

500+ detailed definitions for each step of the Reliability Engineering, Work Management, and Materials Management work streams.

Example of Tools

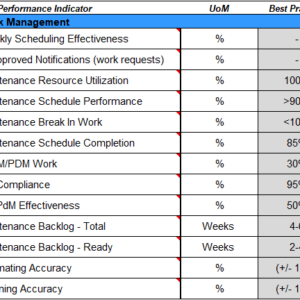

Key Performance Indicators

Maturity Matrix

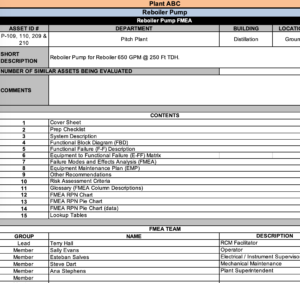

FMEA-EMP Tool

Job Descriptions

RIME Index

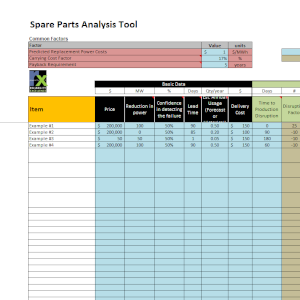

Spare Parts Purchase Tool

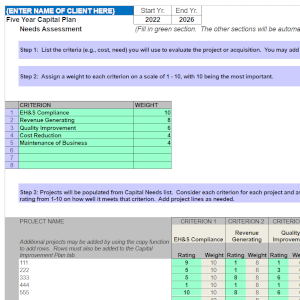

Capital Management Five Yr Planning Tool

Reliability Risks

Planning and Scheduling Checklist

Enterprise Dashboards

Standard business intelligence and custom

dashboards for Enterprise clients.

Enterprise Dashboards

Our system use dashboards visualize logins, eLearning progress, assessments, and more to gauge Playbook adoption and use. We can also design custom dashboards that display operational KPIs, enabling you to make data-driven business decisions.

eLearning Courses

Our eLearning courses grow workforce capabilities in core reliability and asset management knowledge areas. Use eLearning at the beginning of a transformation to align the organization on terminology and approach, for new employee onboarding, or for ongoing professional development.

eLearning Courses

Maintenance Planning and Scheduling

Reliability Centered Maintenance

MRO Storeroom Management

Root Cause Analysis

Reliability Engineering Excellence

Predictive Maintenance Strategy

Includes a maturity level evaluation for each of the following processes:

Includes a maturity level evaluation for each of the following processes:

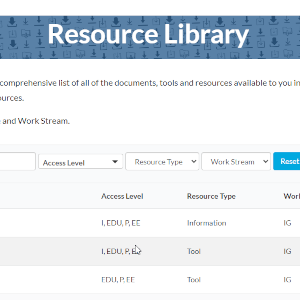

A comprehensive, filterable search list of all of the documents,

A comprehensive, filterable search list of all of the documents, A collection of all business processes, RASIs and coaching cards, plus a curated collection of tools specifically for Reliability Engineering, including:

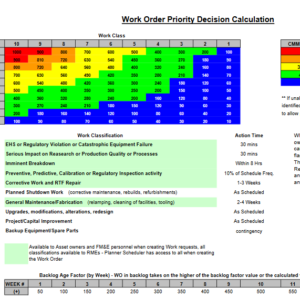

A collection of all business processes, RASIs and coaching cards, plus a curated collection of tools specifically for Reliability Engineering, including: A collection of all business processes, RASIs and coaching cards, plus a curated collection of tools specifically for Work Management, including:

A collection of all business processes, RASIs and coaching cards, plus a curated collection of tools specifically for Work Management, including: A collection of all business processes, RASIs and coaching cards, plus a curated collection of tools specifically for MRO and Spare Parts Materials Management, including:

A collection of all business processes, RASIs and coaching cards, plus a curated collection of tools specifically for MRO and Spare Parts Materials Management, including: A collection of all business processes, RASIs and coaching cards, plus a curated collection of tools specifically for Reliability Engineering, including:

A collection of all business processes, RASIs and coaching cards, plus a curated collection of tools specifically for Reliability Engineering, including: A collection of all business processes, RASIs and coaching cards, plus a curated collection of tools specifically for Reliability Engineering, including:

A collection of all business processes, RASIs and coaching cards, plus a curated collection of tools specifically for Reliability Engineering, including: A collection of all business processes, RASIs and coaching cards, plus a curated collection of tools specifically for Reliability Engineering, including:

A collection of all business processes, RASIs and coaching cards, plus a curated collection of tools specifically for Reliability Engineering, including: